GTR Transformers

Transformer Condition Assessment. Knowledge ‘is’ Power

“GTR believe extending the useful life of a power transformer is the single most important strategy for increasing life of power transmission and distribution infrastructure”

Determining the present condition of a power transformer is an essential step in analysing the risk of failure.

Reasons for Assessment

For providing reliable electrical

energy, it is very necessary to have

highly reliable associated electrical

equipment. The transformer, being a

key element in the transmission and

distribution of electrical energy,

improving its reliability is of utmost

importance. System abnormalities,

loading, switching and ambient

condition normally contributes

towards accelerated aging and

sudden failure, Hence, it is, all the

more essential, to employ on-site

diagnostics followed by quality

maintenance for trouble-free and

reliable operation with minimum

outages.

The cost of failure;

Power transformers are often

situated at strategically critical

locations in power supply systems,

and as a result the financial

consequences of their failure can

easily exceed their actual asset value.

The real challenge lies in

implementing the right action at the

right time.

Given that the average age of power

transformers in most countries is

around 25–30 years and considering

the increase of the typical failure

probability with the transformer age,

action clearly needs to be taken to

ensure their continued reliability and

functionality.

Trafo Assessment areas

Common Failure areas

The following are the major components, which have a direct bearing on reliability of the transformer

Windings and electrical circuit

• Core and clamping structure

• Bushings and external connections

• OLTC On Load Tap Changers

• Cooler equipment and cooling medium

• Control and supervisory equipment

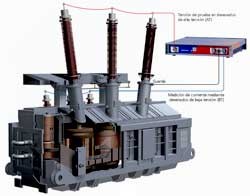

Transformer diagnostic techniques

Several transformer diagnostic techniques are used by GTR onsite to determine the matured transformer life expectance & health. They can be grouped into Electrical tests applied to the transformer active part on-site and Insulating Oil extracted for laboratory analysis.

Evaluation for Analysis

GTR Transformers are able to

evaluate previous Transformer

maintenance records including oil

analysis samples along with a visual

external inspection to determine

which units are showing signs of

degradation and vulnerability.

When a unit has been selected for

analysis our experienced engineers

equipped with the latest industry

leading technology will arrive at your

facility and perform onsite tests and

conduct oil sampling from various

locations using expert methods to

ensure accuracy of reporting.

GTR transformers will analyse the

collected measurements in house

providing the customer with a life

expectance in present state and

recommendations of extending life.

Identify weaknesses to manage and

control or plan for mitigating

measures.

Our software delivers comprehensive

reports to ensure future condition

monitoring has an accurate reference

to benchmark.

Onsite measurements

Transformer Condition Indicator – Electrical Tests

Turns Ratio Test

The transformer turns ratio (TTR)

test detects shorts or severe

tracking between turns of the same

coil, which indicates insulation

failure between the turns. These

tests are performed with the

transformer de-energised and may

show the necessity for an internal

inspection or removal from

service.

Short Circuit Impedance

Percent Impedance or Leakage

Reactance, these tests are

conducted in the field and

compared to nameplate

information, previous tests, and

similar units to detect deformation

of the core or windings caused by

shipping damage, through faults, or

ground faults. Some difference

may be expected between

nameplate and field test results

because factory tests are

conducted at full load current.

Field connections, test leads and

jumpers also play a significant role

in test results and it is impossible

to exactly duplicate the factory test

setup.

Core-Ground Resistance Test

The transformer core is

intentionally grounded through

one connection. The core-toground resistance test can detect if

this connection is loose. It can also

detect whether there are other

undesired and inadvertent,

grounds. If the intentional core

ground is intact, the resultant

resistance should be very low. To

check for unintentional core

grounds, remove the intentional

ground and megger between the

core and the grounded

transformer tank. This test should

produce very high resistance,

indicating that an unintentional

ground is not present. This test is

to supplement dissolved gas

analysis that shows generation of

hot metal gases (i.e., methane,

ethane, and ethylene) and to

indicate if a spurious, unintentional

core ground is the problem.

Experience can help locate the

source of the problem.

Windings Insulation Resistance

This basic insulation resistance

test is used to determine the

integrity of windings and the

condition of windings insulation.

Transformer windings are exposed to environmental factors such as

dirt, grease, temperature, stress,

and vibration which can lead toinsulation failure. The test is

performed after the initial

installation of transformer and as

part of the routine maintenance.

Winding DC Resistance Measurement

GTR Transformers are able to

evaluate previous TransformerCareful measurement of winding

resistance can detect broken

conductor strands, loose

connections, and bad contacts in

the tap changer. Results from

these measurements may indicate

the need for an internal inspection.

This information supplements

dissolved gas analysis (DGA) and is

useful when DGA shows generation

of heat gases (i.e., ethane, ethylene,

methane). Test results are

compared between phases or with

factory tests. When comparing to

factory tests, a temperature

correction must be employed.

Furthermore, OLTC dynamic

resistance can be measurement to

determine the contact resistance.

maintenance records including oil

analysis samples along with a visual

external inspection to determine

which units are showing signs of

degradation and vulnerability.

When a unit has been selected for

analysis our experienced engineers

equipped with the latest industry

leading technology will arrive at your

facility and perform onsite tests and

conduct oil sampling from various

locations using expert methods to

ensure accuracy of reporting.

GTR transformers will analyse the

collected measurements in house

providing the customer with a life

expectance in present state and

recommendations of extending life.

Identify weaknesses to manage and

control or plan for mitigating

measures.

Our software delivers comprehensive

reports to ensure future condition

monitoring has an accurate reference

to benchmark.

Frequency Response Analysis

Frequency Response Analysis

(FRA) or Sweep Frequency

Response Analysis (SFRA) can

determine if windings of a

transformer have moved or

shifted. It can be done as a factory

test prior to shipment and

repeated after the transformer is

received on site to determine if

windings have been damaged or

shifted during shipping. This test

is also helpful if a protective relay

has tripped or a through fault,

short circuit, or ground fault has

occurred

A sweep frequency is generally

placed on each of the high voltage

windings and the signal is detected

on the low-voltage windings. This

provides a picture of the frequency

transfer function of the windings.

If the windings have been

displaced or shifted, test results

will differ markedly from prior

tests. Test results are kept in

transformer history files so they

can be compared to later tests.

Results are determined by

comparison to baseline or previous

measurements or comparison to

units of similar design and

construction.

The power factor value of 0.5%

was used as acceptance criteria for

new transformers. Sudden

increases in value of power factor

over time are taken as a sign of

deterioration of the insulation

condition. The power factor on

serviced-aged transformer in good

condition should be in the range of

0.5% to 1.5%

Insulation power factor test of windings and bushings

Power factor is a ratio of dielectric

loss (or watt loss) to the charging

volt-amperes (or apparent power

input). It is a property of the

electrical insulation system and a

measure of the electrical losses in

the insulation when subjected to

an applied alternating voltage.

Power factor testing is the single

most valuable method of obtaining

data for determining insulation

quality. A high loss may indicate

problems in the insulation

structure. Normal ageing of an

insulating material will also

cause dielectric loss to increase.

Contamination of insulation by

moisture or chemical substances

may cause losses to be higher than

normal.

Dielectric Frequency Response

DFR also known as ‘Polarisation

Spectrum Measurement’ is used to

assess the moisture content of the

cellulose insulation located

between the primary and

secondary winding. This test is

normally carried out as part of the

maintenance routine to assess

insulation conditions. Insulation

performance can be affected by

paper aging or increased moisture

level due to broken seals. This

measurement is also used for new

transformers to prove the low

moisture content after the drying

process.

Degree of Polymerisation

Frequency Response Analysis

(FRA) or Sweep Frequency

ResponsWinding insulation (cellulose)

deterioration can be quantified by

analysis of the Degree of

Polymerization (DP) of the

insulating material. This test gives

an indication of the remaining

structural strength of the paper

insulation and is an excellent

indication of the remaining life of

the paper and the transformer

itself. This requires analysing a

sample of the paper insulation in a

laboratory to determine the

deterioration of the molecular

bonds of the paper.

e Analysis (SFRA) can

determine if windings of a

transformer have moved or

shifted. It can be done as a factory

test prior to shipment and

repeated after the transformer is

received on site to determine if

windings have been damaged or

shifted during shipping. This test

is also helpful if a protective relay

has tripped or a through fault,

short circuit, or ground fault has

occurred

Partial Discharge

Partial discharge (PD) can cause

irreversible damage to power

transformer insulation,

long before the insulation actually

fails. Even upon detection and

analysis, it is

essential to know exactly where

insulation defects are located in

the transformer.

GTR Transformers perform PD

Online diagnostics without the

need for outage using the latest

technology.

Oil analysis

Transformer Condition Indicator – Insulating Oil

Dissolved gas analysis is the most

important factor in determining the

condition of a transformer. Being

performed more frequently than

other tests, it may be the first

indication of a problem. Insulating oil

analysis can identify internal arcing,

bad electrical contacts, hot spots,

partial discharge, or overheating of

conductors, oil, tank, or cellulose.

The “health” of the oil reflects the

health of the transformer itself.

Dissolved gas analysis (DGA) consists

of drawing transformer insulating oil

samples from the transformer tank

and sending the samples to a

commercial laboratory for analysis.

The most important indicators are

the individual and total dissolved

combustible gas (TDCG) generation

rates, based on IEC and IEEE

standards. Although gas generation

rates are not the only indicator, they

are reasonable for use in determining

the condition indicator score.

Furanic analysis may indicate a

problem with the paper insulation

which could affect transformer

longevity. A baseline furanic analysis

should be made initially and repeated

if the transformer is overheated,

overloaded, aged, or after changing or

processing the oil.

Physical tests such as interfacial

tension (IFT), acidity, moisture

content, and dielectric strength

usually indicate oil conditions that

can be remedied through various

reclamation processes. Therefore,

they are not indicative of overall

transformer condition that would

lead to replacement.