Power Transformer Installation & Commissioning

Our team of Transformer Technicians have a

over 60 years’ experience Installing &

Commissioning Power Transformers and

Reactors across the world for all the leading

OEM’s within the Power Utilities Industry.

This experience makes GTR Transformers an

extremely competent and safe transformer

Installation & Commissioning contractor.

Complete transformer installation assembly & initial offload supervision

GTR Technicians are competent in overseeing

the Transformer ooad from haulage

contractor to nal positioning to the substation plinth. Analysing Impact recorder data

and performing core insulation checks is a

given. Positioning Anti-Vibration pads and

video recording the jacking down process is all

part of what we do.

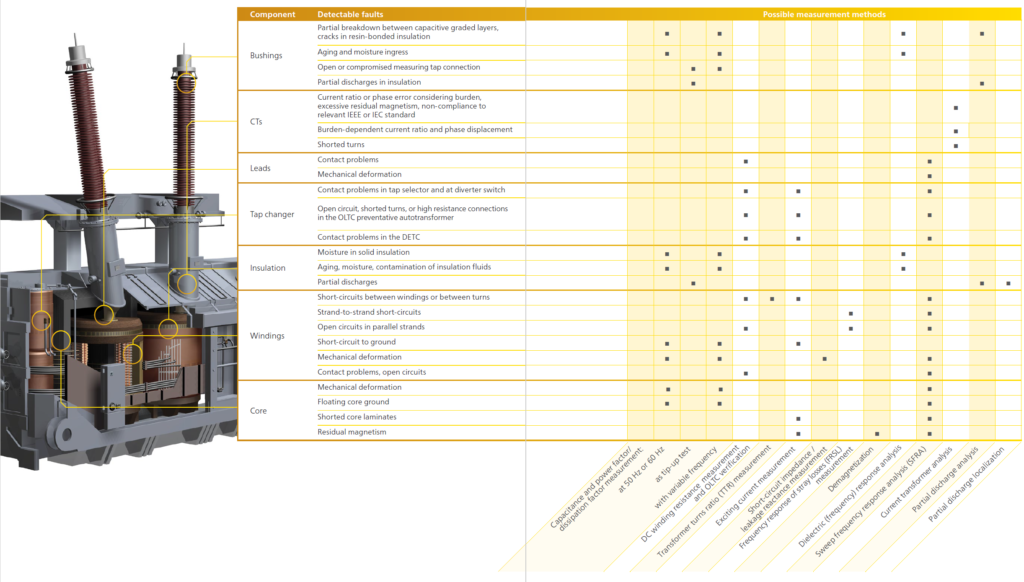

Results are compared with the manufacturer data and factory test results. Common Electrical Tests are part of routine checks of transformer health and are also used to check the on-load tap changer and the condition of OLTC contacts.

Installation

Our Technicians coordinate all ancillary

deliveries including safe operation of

cranes/telehandlers before the assembly prechecks commence.

During the installation GTR Technicians work to

strict safety instruction detailed within Method

Statements and Factory assembly protocol.

Risk is mitigated and reduced prior to any shift

by means of site-specic RA. Site conditions

within outdoor sub-stations change hourly, risk

is therefore continually monitored.

Assembling cooler banks, pipework,

conservators, turrets and bushings, Current

Transformers, OLTC, ancillary components,

kiosks and eld wiring is all part of Technicians

duty. Experience brings eciencies which help

our customer eld installation budgets.

Commissioning

GTR prides itself on vast and varied Sub-Station

commission knowledge. Being a core business

practice GTR have the latest and most

sophisticated test rigs available in todays

market, coupled with decades of experienced

sta GTR will rigorously test and compile

comprehensive test reports post installation

GTR Transformers’ Engineering knowhow

provides its clients with the comfort &

reassurance that its product is being handled

with care by consciences Technicians.

The Oil ll element is so critical to a

Transformers longevity of service that such

activity is continually monitored. Our senior

Technicians are competent Oil plant operators

and therefore skilling to diligently supervising

oil plant contractors in making sure exact

factory protocol is followed.

Documentation and Reporting

- Automated Test Reports from specialised test and commissioning equipment

- Customized and system specific test documentation

- Detail report on work completion with test results and further recommendations

Maintenance

The main purpose for all the above routine and maintenance tests and analysis is to detect transformer developing faults before a major failure occurs. In case of a major fault the only system that will isolate the transformer from the network and prevent from future extensive damages is the protection system. GTR specialises in testing and commissioning of protection schemes and protection relays and conducts secondary injections using specialised test equipment with dedicated transformer protection function modules. GTR also performs overall function testing to verify overall system integration, including mechanical trips from transformer protection devices.

- Installation and refurbishment of protection relays, control devices and instrumentation in generation

- Secondary injection test on protection relays and scheme functional checks on protection & control panels

- Evaluation of site maintenance requirements

- Preparation of maintenance schedules

- Equipment specification and purchase

- Supervision of contactors

Test Equipment

- OMICRON CMC 256/356 – Secondary Injection of protection relays and instrumentation and Transducer Testing

- OMICRON CPC 100 – Multifunctional Primary Test System (Current, Voltage, Micro Ohm Resistance, etc)

- OMICRON TESTRANO 600 + TD1 – Common Electrical Tests, Static & Dynamic Dc Winding Resistance, Tap Changer, Short-circuit impedance / leakage reactance measurement, Excitation current, Capacitance & Power Factor of the windings and bushings, FRSL.

- OMICRON CT Analyser – Protection and metering current transformers (Ratio and phase angle, CT excitation and saturation burden impedance, winding resistance, CT Polarity)

- OMICRON FRANEO – Sweep Frequency Response Analysis (SFRA)

- OMICRON DIRANA – Dielectric Frequency Response (DFR) – ‘Polarisation Spectrum measurement’

- Buchholz Dry Air Pump – Buchholz relay function test

- Hart Scientific 7380 Temperature Bath – WI temperature sensors calibration

- PT100 Simulator – Winding temperature simulator

- MIT515KV Megger – Winding insulation resistance test set

Oil Sample Tests

As transformer oil is contact with every internal

component of a transformer it contains a great

deal of diagnostic information.

GTR can assist in conducting laboratory

analysis of transformer oil samples to provide

an advance warning of developing fault

conditions. Standard supervision and

maintenance analysis include tests such as

dielectric strength, water content, acidity,

colour, odour and visible contaminants.